PWHT

Induction Post Weld Heat Treatment: A Complete Guide to Process and Advantages

Induction post weld heat treatment (PWHT) plays a critical part in further developing weld respectability. It's an interaction used to ease the pressure, further develop strength, and upgrade the general nature of welded joints. By utilizing enlistment warming, the welded regions are warmed to exact temperatures, guaranteeing more grounded and more dependable associations.

This strategy is broadly taken on in businesses like oil and gas, pipelines, and large equipment fabricating.

What is Induction Post-Weld Heat Treatment?

Induction post weld heat treatment PWHT utilizes electromagnetic enlistment to warm the welded material to a particular temperature. This cycle helps in decreasing the leftover pressure that develops during welding. After welding, metals experience pressure because of quick warming and cooling, which can prompt imperfections or breaking. Induction PWHT assuages these burdens by slowly warming and cooling the welded material.

For what reason is PWHT significant for weld quality?

Induction PWHT is fundamental for upgrading weld strength and forestalling material disappointment. While welding metals like carbon steel, the cooling rate after welding can cause lingering pressure, prompting breaks or debilitating.

PWHT smooths out these burdens and reestablishes the material's pliability. This results in more strong, stable, and dependable welded joints. Businesses that depend on basic weld strength, like tension vessels and primary steel, utilize this method for better execution.

How Does Induction PWHT Further Develop Weld Strength?

Induction PWHT guarantees the welded metal keeps up with its primary respectability over the long run. This interaction further develops strength by lessening weak zones brought about by welding. It additionally improves the material's sturdiness, making it less inclined to cracks. When performed accurately, PWHT keeps up with the compound and actual properties of the material, which is crucial for security and life span in requesting modern applications.

The Course of Acceptance PWHT

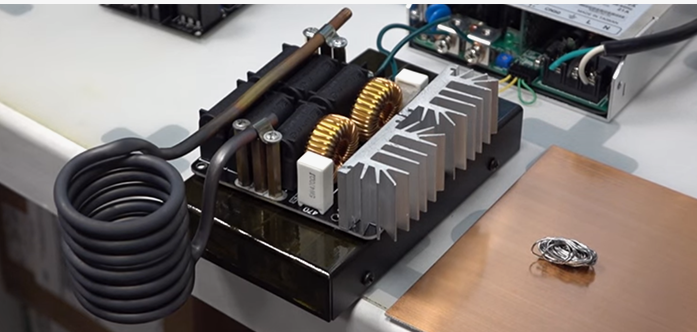

Readiness: The weld is cleaned, and warming curls are set around it.

Warming: Electromagnetic acceptance warms the weld to the ideal temperature.

Holding: The material is held at the objective temperature for a predefined term.

Cooling: Progressive cooling assists with limiting leftover pressure and preventing material mutilation.

This controlled warming and cooling guarantee uniform outcomes, upgrading weld quality and diminishing the gamble of disappointment.

Benefits of Induction PWHT

Exact Temperature Control: Takes into account more precise intensity therapy than conventional techniques.

Energy Effectiveness: Acceptance warming is quick and consumes less energy.

Quicker Cycle: Acceptance PWHT decreases personal time and increases efficiency.

Reliable Outcomes: Guarantees uniform intensity circulation, bringing about more grounded welds.

Enterprises Profiting from Induction PWHT

Oil and Gas: For pipelines and strain vessels that require solid welds.

Aviation: guarantees basic parts are liberated from pressure and imperfections

.

Development: Works on the strength and life span of primary steel parts.

Power Age: guarantees pressure vessels and channeling frameworks perform ideally.

FAQs

1. What is the reason for post-weld heat treatment?

Post-weld heat treatment alleviates leftover pressure and improves weld strength.

2. Why use Induction PWHT?

Acceptance gives quicker, more exact warming, further developing energy effectiveness and efficiency.

3. How does PWHT prevent breaking in welded joints?

By diminishing leftover burdens, PWHT forestalls breaks and works on the general strength of the material.

4. Is induction PWHT reasonable for all metals?

It's generally utilized for carbon preparations and composites, particularly where stress help is basic.

5. What amount of time does the induction PWHT deal with require?

The term fluctuates in light of the material sort and weld thickness, yet it's quicker than customary techniques.

Conclusion

Induction PWHT post-weld heat treatment is an effective and exact technique for improving weld strength and quality. By decreasing lingering pressure and working on the material's durability, it guarantees longer-enduring, more solid welds. This strategy is great for enterprises requiring elite execution welding arrangements, like oil and gas, development, and aviation. Taking on Induction PWHT improves efficiency, energy effectiveness, and the general solidness of welded parts.